Casting Defects: Understanding, Causes, and Solutions

Introduction to Casting Defects

Casting is a vital manufacturing process where liquid material is poured into a mold and allowed to solidify. This process is used to create complex shapes and structures from metals, plastics, and other materials. However, casting is not without its challenges. Defects can occur, impacting the quality, strength, and usability of the cast product. Understanding these defects, their causes, and potential solutions is crucial for manufacturers aiming to produce high-quality castings.

Common Types of Casting Defects

- Porosity

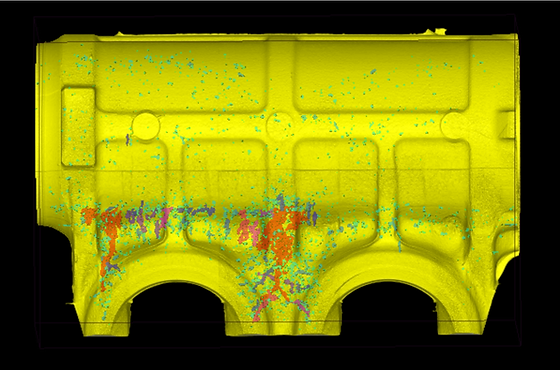

- Gas Porosity: Occurs when gas is trapped within the casting, forming bubbles or voids. This can happen due to improper venting, high moisture content, or excessive gas in the melt.

- Shrinkage Porosity: Results from the metal shrinking as it cools and solidifies, leading to voids. This is often due to poor mold design or inadequate feeding systems.

- Inclusions

- Slag Inclusions: Non-metallic materials, such as slag, become trapped in the casting. This is typically caused by inadequate slag removal or improper pouring techniques.

- Oxide Inclusions: Formed when oxides from the molten metal are not properly removed. This can be due to a lack of protective atmosphere or insufficient fluxing.

- Cold Shuts

- Occur when two streams of liquid metal do not fuse properly during pouring, leading to a weak seam. This is often due to low pouring temperature or improper mold design.

- Hot Tears

- Cracks that occur when the metal is still hot and under stress during solidification. This can be caused by uneven cooling rates, poor mold design, or alloy composition.

- Misruns

- Happen when the molten metal does not completely fill the mold cavity, resulting in an incomplete casting. Causes include low pouring temperature, slow pouring speed, or high viscosity of the molten metal.

- Mold Shifts

- Occur when the mold halves shift relative to each other during pouring, leading to a misaligned casting. This is often due to improper mold assembly or inadequate clamping.

Causes of Casting Defects

- Material Issues

- Impurities in the raw materials or incorrect alloy compositions can lead to various defects. Ensuring high-quality materials and proper alloying can mitigate these issues.

- Process Parameters

- Inaccurate control of temperature, pouring speed, and pressure can cause defects. Consistent monitoring and control of these parameters are essential for producing defect-free castings.

- Mold Design and Preparation

- Poorly designed molds or improper preparation can lead to defects. Proper mold design, adequate venting, and appropriate gating systems are crucial.

- Human Error

- Mistakes during the casting process, such as incorrect mold assembly or inadequate inspection, can result in defects. Training and experience of personnel are vital to minimize human error.

Solutions and Preventive Measures

- Material Quality Control

- Use high-purity raw materials and correct alloy compositions. Implement rigorous inspection and testing procedures for incoming materials.

- Optimized Process Parameters

- Maintain consistent control over pouring temperature, speed, and pressure. Use advanced monitoring systems to ensure these parameters are within specified ranges.

- Improved Mold Design

- Design molds with proper venting, gating, and feeding systems. Use simulation software to predict and address potential issues before actual casting.

- Training and Skill Development

- Regular training programs for personnel to enhance their skills and knowledge. Emphasize the importance of attention to detail and adherence to standard operating procedures.

- Inspection and Testing

- Implement robust inspection techniques, such as non-destructive testing (NDT), to detect defects early. Use advanced imaging technologies like X-ray or ultrasonic testing for thorough inspection.

- Continuous Improvement

- Foster a culture of continuous improvement where feedback from inspection and testing is used to refine processes. Encourage innovation and adaptation of new technologies to improve casting quality.

Conclusion

Casting defects are a significant challenge in the manufacturing industry, affecting the quality and performance of cast products. By understanding the types, causes, and solutions for these defects, manufacturers can take proactive measures to minimize their occurrence. Through material quality control, optimized process parameters, improved mold design, skilled workforce, rigorous inspection, and a culture of continuous improvement, it is possible to produce high-quality castings that meet stringent industry standards.